Gantry 3D Spin

Gantry 3D Spin

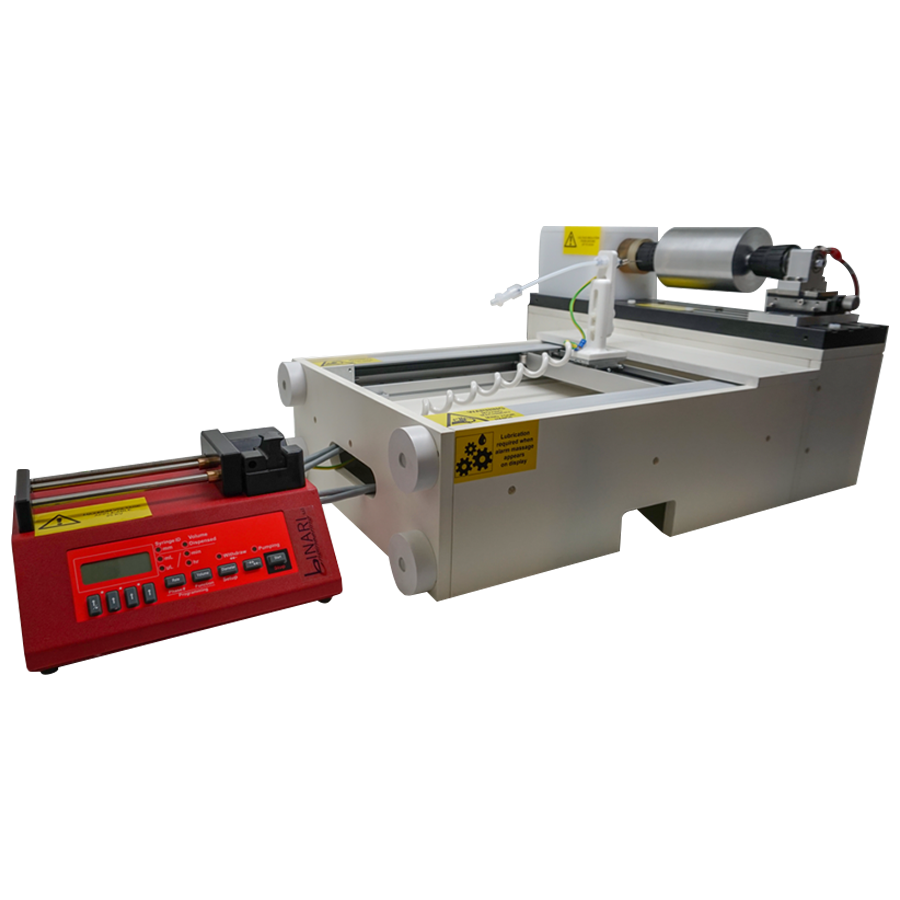

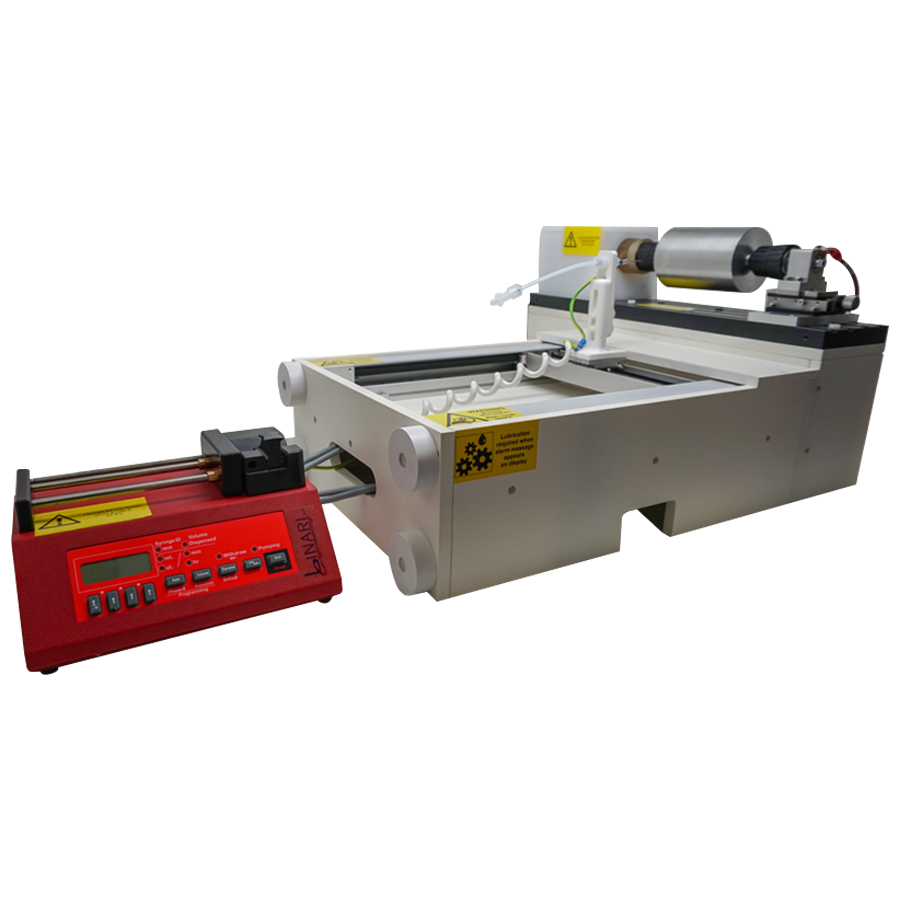

A complete solution for those in need to control the distance between needle and collector during the whole electrospinning process.

Machine 3D Spin is a high-tech system, safe, compact, and ready to use.

The most versatile electrospinning system to obtain fibers with uniform thicknesses

A complete solution for those in need to control the distance between needle and collector during the whole electrospinning process.

The device is a high-tech system, safe, compact, and ready to use.

Thanks to the G-code interpreter you’ll be able to draw the desired trajectory of the table through a CAD software. The CSV interpreter allows you to create work programs in a simple way through spreadsheets.

Setting up the position of the needle, you can deposit fibers with different thicknesses on your collector.

Moreover, that allows you to increase the distance between needle and collector if a longer trajectory is required for solvent evaporation.

Please notice that the basic configuration includes only a plate collector.

The 3d spin is a versatile system which allows the creation of fibers with both aligned or random structure, depending on the configuration.

The basic configuration includes a plate collector. As optional, our isolated Easy Drum HSI can be added for both a vertical or horizontal configuration

KIT INCLUDES:

- Electrospinning Station Hood

- Syringe Pump- Single Channel

- Rotation Unit

- 2D Spin

- Glass Syringes

- HV Generator 40kV

- Vertical Support 200*300mm

- PVC Modular Support 200*300mm

- Plate Collector 100*100mm

- Luer Needles - 12pcs - flat OD: 0.8mm L:15mm

- Multiple Needles 4 Tips

Share